Surge Analysis in a Pipeline Network

Surge Analysis in a Pipeline Network

To detect the peak pressure surge in a pipe system and for proper pipe sizing, a method of analyzing the pressure changes in a pipe system called surge analysis is performed. In any pipeline system, the fluid flow must be started and stopped by

pump/valve operations. During these operations, when a sudden change in the kinetic energy of the fluid exerting pressure exceeding the Maximum Allowable Operating Pressure (MAOP) occurs, it causes severe damages to the pipe network such as dents, buckling and bursting of pipes, deformation of the pipe supports, damages to the pumping systems and instruments damage.

Reasons for the cause of pressure surge:

This sudden change in pressure arises due to the following reasons:

- Sudden opening/closure of valves (cross sectional flow area variation)

- Sudden start/stop of the pumping systems

- Starting up /shutting down of Multiple pumps

- Unexpected power failure

- Instrumentation failure

- A sudden release of air

- oscillation of a tank

- Sudden blockage of the flowing fluid

Advantage of the simulation:

In order to prevent such a catastrophic damage to the pipe systems, an engineering process evaluation of the pipe system must be carried out before its operation. A computerized simulation replicating the real life functioning of the pipe system is the essential tool, the industrial experts would look forward to. A CFD analysis could also be carried out for the same. To acquire the accurate behaviour of the system, the suitable inputs as in real life conditions are to be provided. The inputs required are

- Piping Isometric Drawings.

- Piping and Instrumentation Diagram (P&ID)

- Process Engineering Flow Scheme (PEFS) / Process Flow scheme (PFS)

- Any Other relevant information

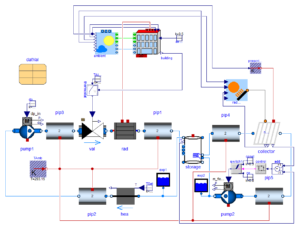

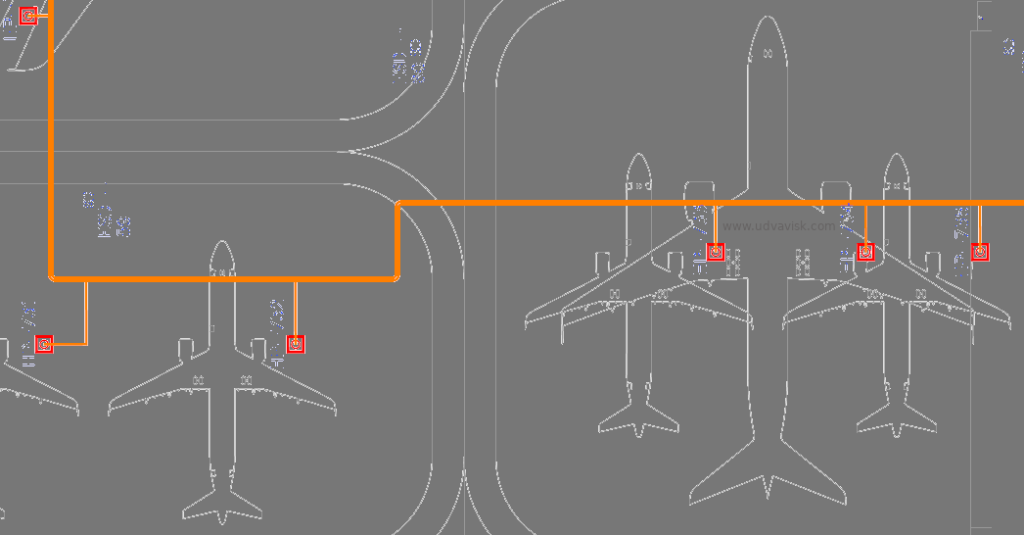

A steady state simulation calculates the time invariant temperature, pressure and fluid flow behavior of the piping network. The output from the steady state simulation could be used to provide initial conditions of a time variant transient simulation. A transient simulation predicts the response of the pipeline system to any changes in the system variables under suitable operating conditions.

Solution and control measures from the simulation:

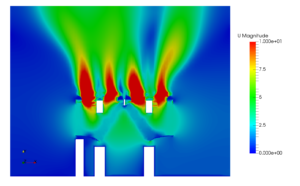

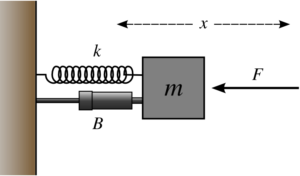

The pressure waves generated travel with the velocity of sound and cause transient disturbances throughout the flow system. The extent of the velocity of the pressure waves depend on the elasticity of the fluid and elastic properties of the pipe such as material property and wall thickness. From the result of the simulation, the areas of peak pressure could be found at any point (node) in the system. To stop the kinetic energy from being converted into elastic deformation, is the sole purpose of the surge control methods. The abnormalities in the identified areas/points are addressed with cost effective and efficient surge control techniques.

The following are some of the surge control techniques used in industries.

- Using surge tanks, water towers, reservoirs, or air vessels to convert kinetic energy into potential (strain) energy at problem areas.

- Rigid pipework to withstand the pressure surge. (change of pipe material)

- Increasing pipe diameter to reduce the average velocity of the flow

- Regulating the flow with devices such as pressure regulators, pressure relief valves, check valves, bypass valves, fluid accumulators, surge anticipation valves

- Modification of Valve closing and opening times to maintain optimum operating conditions

These changes can be reflected in the computerized simulation and several iterations with different working conditions can be tested and the efficient solution is filtered out. The areas where the surge analysis will play a key role in the design and

optimization of the pipe network are,

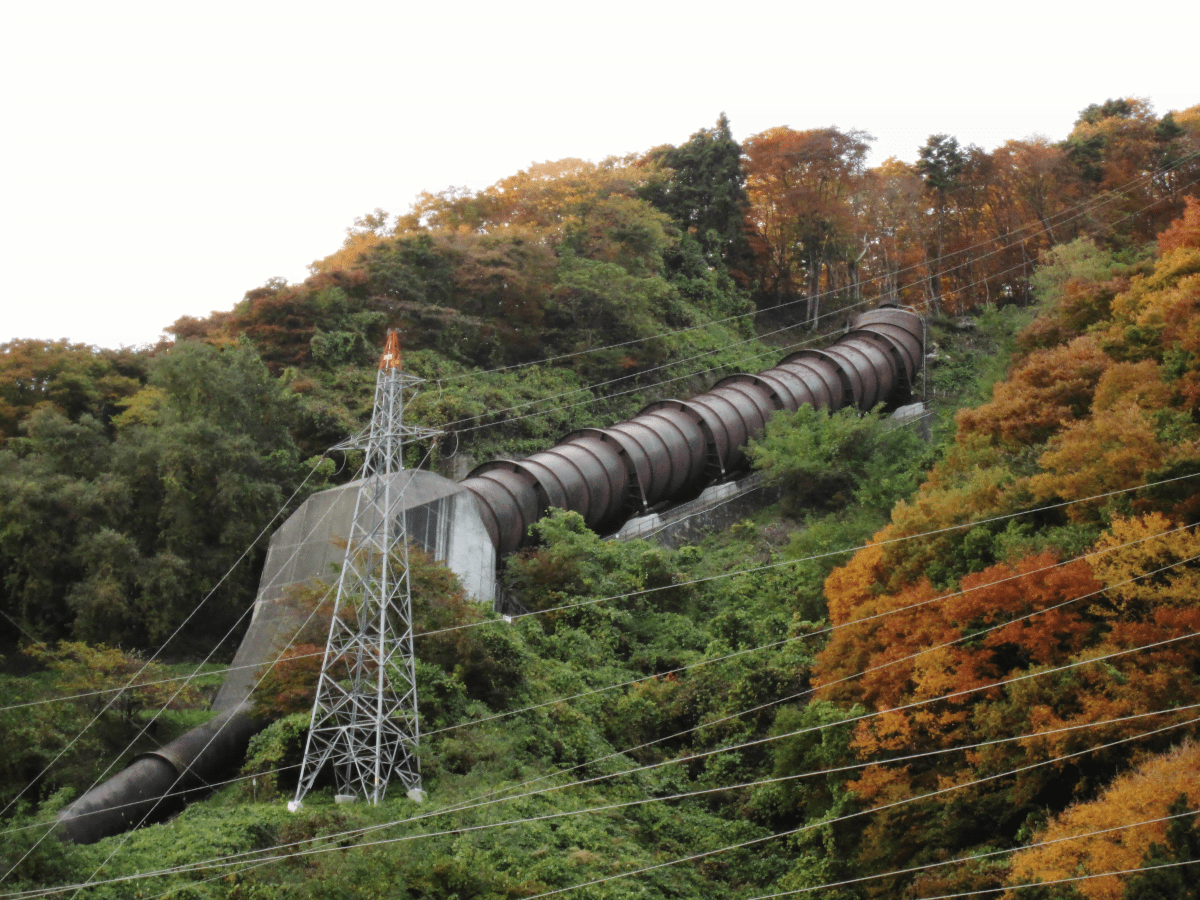

- Oil, water and gas pipelines

- Water distribution and treatment plants

- Refining & Petrochemical Industries

- Industries where fluid is transported over long pipelines

- Fueling and filling stations

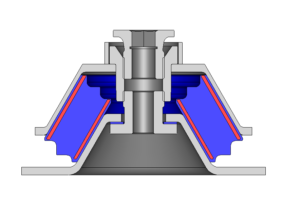

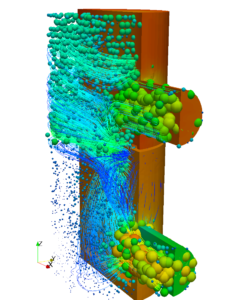

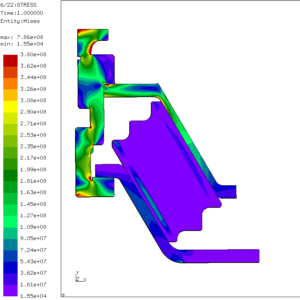

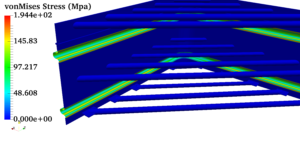

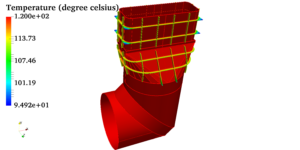

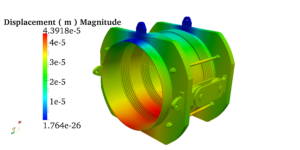

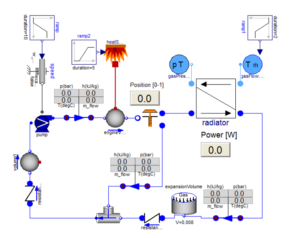

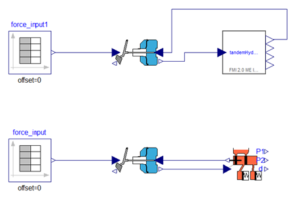

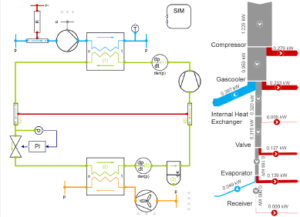

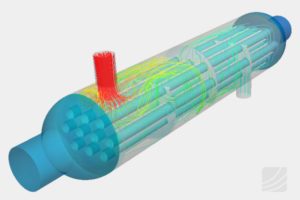

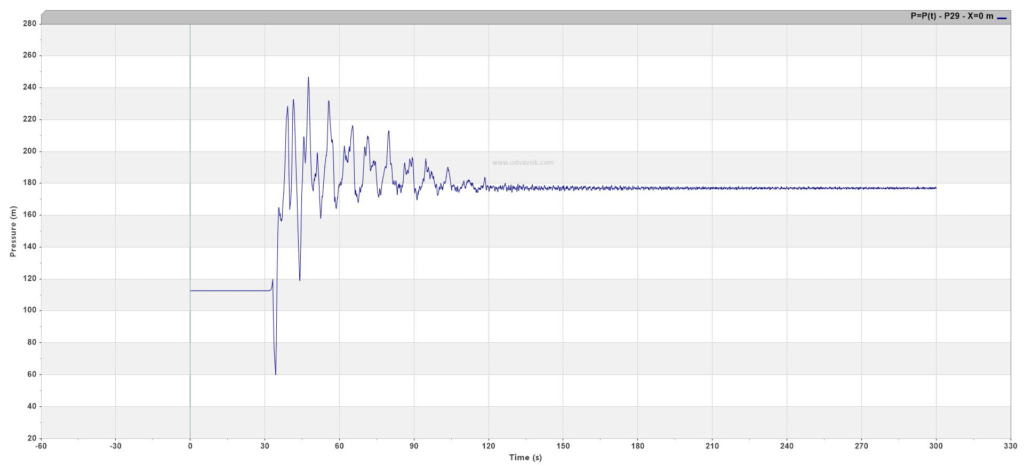

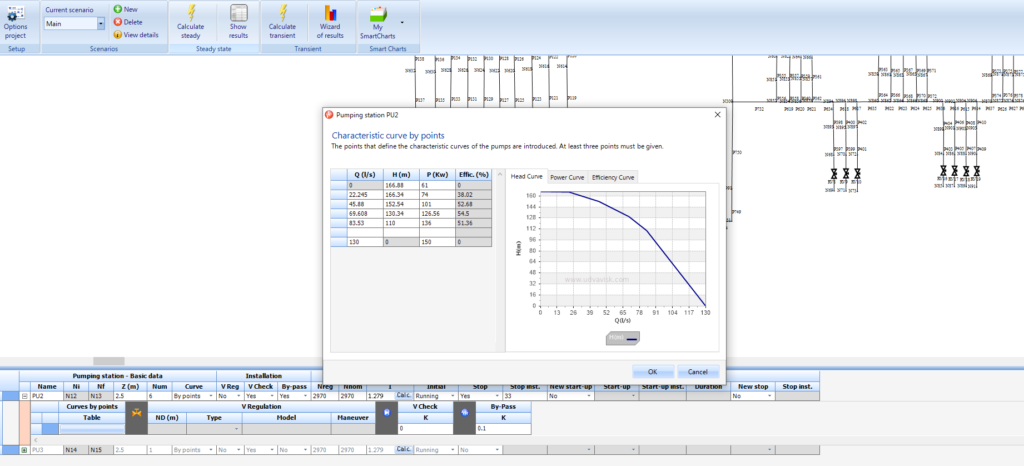

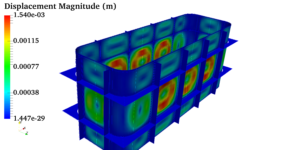

The following are sample images from the Surge Analysis Study carried out by us,

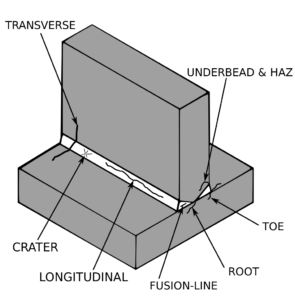

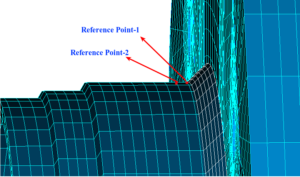

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.