CFD analysis for process industry : basket strainer

CFD Analysis for Process Industry : Basket Strainer

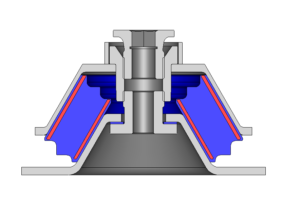

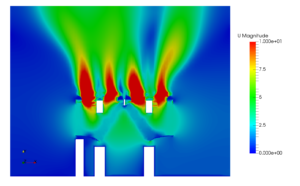

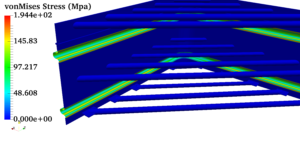

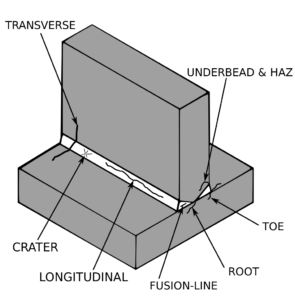

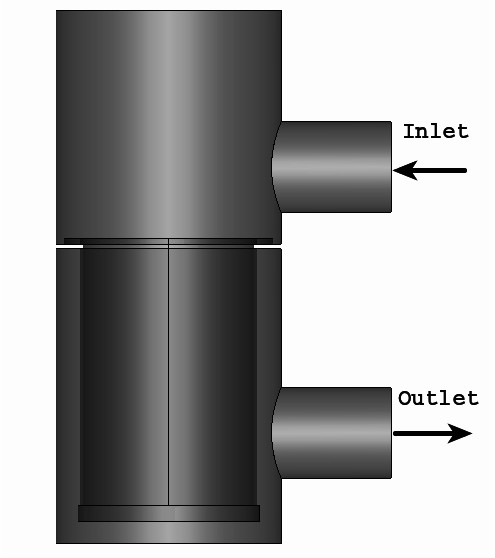

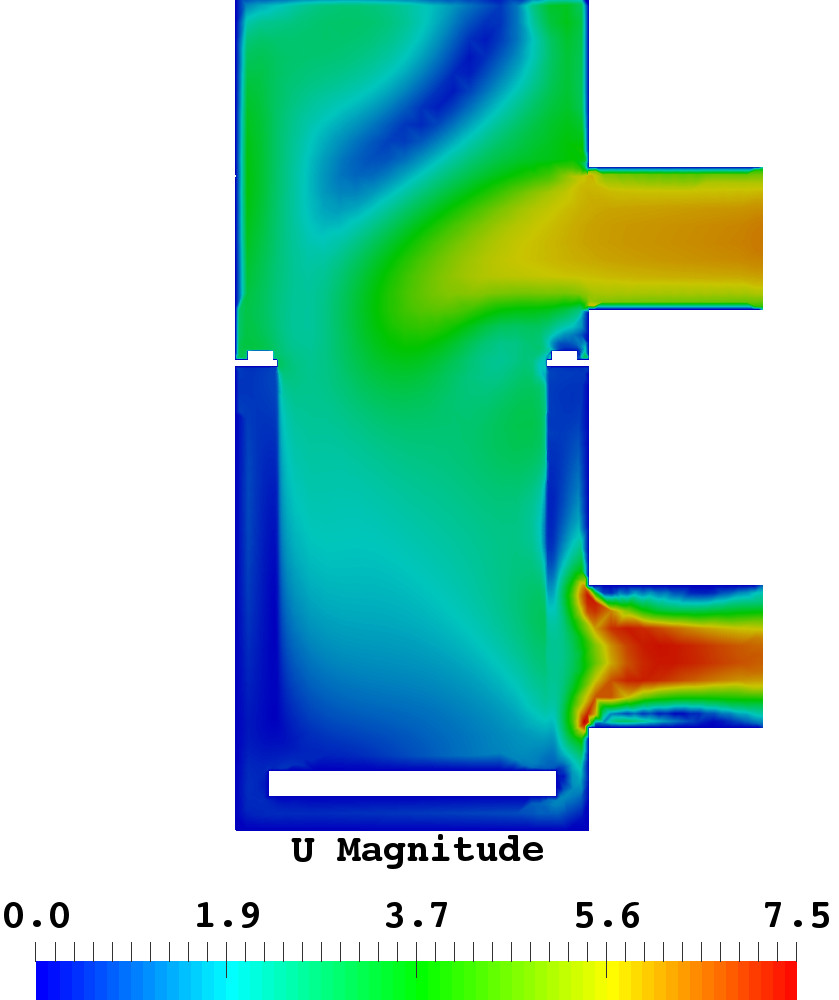

Strainers are used in processing plants and chemical industry as a filtering device. The filtration process involves flow through narrow passages, which causes high pressure drop or head-loss. Besides the losses in filter screens, there are other component of head loss such as during entry and exit pipes, also due to expansion and contraction at junctions. Theoretically, pressure drops increase non-linearly with increasing flow rates. Computational Fluid Dynamics (CFD) is useful to understand the cause of pressure drops in industrial strainers.

In this case-study, the pressure drops across various locations of an off-line basket strainer for different strainers is determined using CFD analysis. The study is carried for a basket strainer with perforated sheet with wire mesh.

Challenges

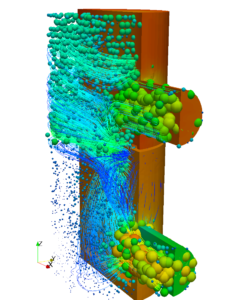

- Modeling the porous zone for the perforated sheet and wire mesh.

- Finding the Darcy and Forchheimer coefficients for the porous zone.

- Finding the correct turbulence model.

- Maintaining the Y+ value.

Results

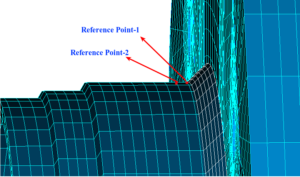

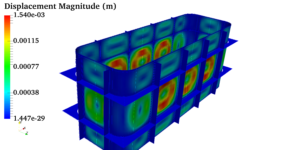

- From the analysis flow coefficients are calculated, along with total head loss.

- The expansion and contraction losses can be estimated from the analysis.

- Any possible zone of flow separation can be determined.

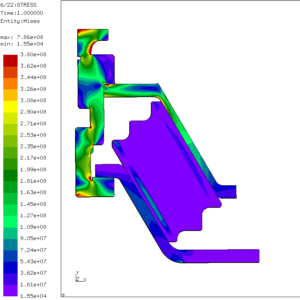

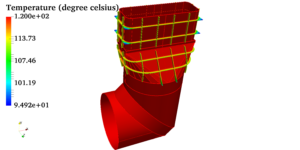

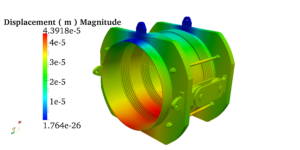

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.