CFD Analysis of Dipping and Drain-out during E-Coating

CFD Analysis of Dipping and Drain-out during E-Coating

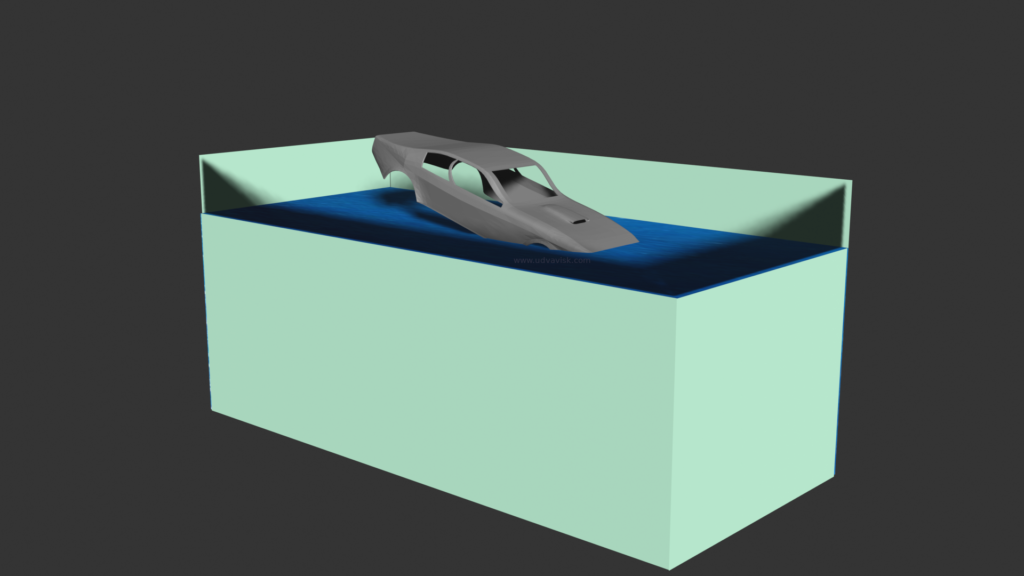

The car bodies need to be coated uniformly using paints to slow down the process of rusting and corrosion. Dipping is the process where the entire car body is dipped into a vat of paint. It also protects the car from sun fading in all the seasons. But, the dipping process is less effective if the paint can’t cover the entire car body uniformly. Many areas are prone to rust and corrosion. Though there are many technologies which have been developed over the decades in surface coating of car bodies, electro coating has been proved to be the most effective method. Usually electro coating of cars include many steps,

Pre cleaning (Removal of dirt and grease)

Phosphating (Treating with phosphoric acid to protect from corrosion)

Electro Coating (Dipping car bodies into the electro coat tank)

Rinsing ( To remove paint clings)

Baking (Heating in an oven to make the bond stronger)

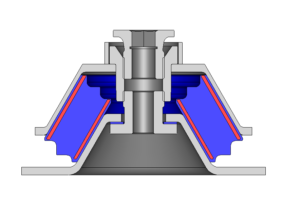

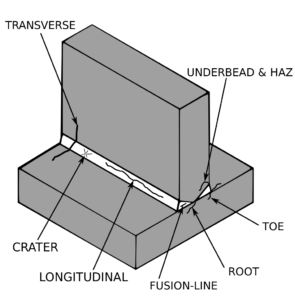

The electro coating tank made of steel contains fresh paint, resin and binder. Here, the car body acts as a cathode while tank acts as anode. When electric current is passed, the paint binds strongly to the surface of the body. A thin layer of film is created near the car body. The efficiency depends on deposition of paints into the car body. A temperature control unit is also connected to the electro coat tank for controlling the temperature of the electro coat tank. The difficulties faced in electro coating process are

Edge Coverage (The edges are not uniformly covered with paints)

Rust and corrosion due to non-uniform coating

Liquid carry overs

Badly painted areas

Scope of CFD

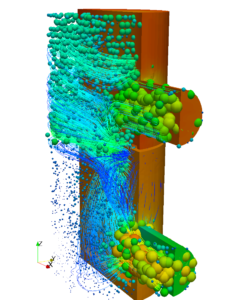

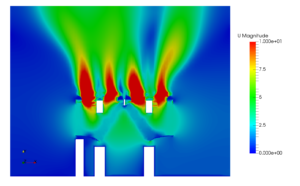

CFD is a perfect tool to analyse the coating quality at the design stage. With the help of a Computational Fluid Dynamics (CFD) simulation,

Time related liquid carry overs could be estimated.

Local Residual liquid ponds could be visualized.

The smearing and interface phenomena between the car body and the paint could be analysed.

The coating quality (Badly painted areas and edges) over the car bodies could be estimated.

The temperature distribution could also be checked.

Fluid flow physics visualization inside the tank.

The following animation illlustrates the Dipping and Drain out operations :

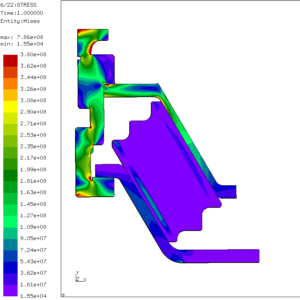

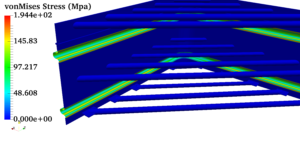

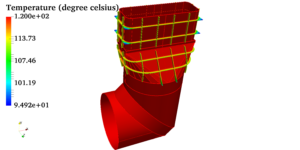

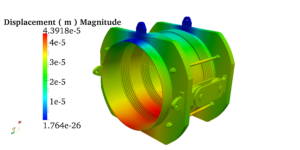

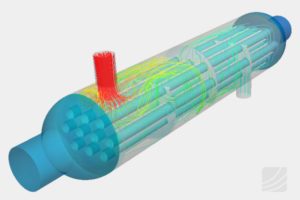

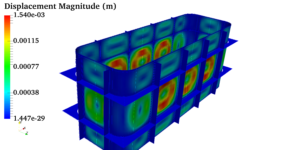

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.