CFD Analysis of Duct Flows and Mitigation of Flow Induced Vibration

CFD Analysis of Duct Flows and Mitigation of Flow Induced Vibration

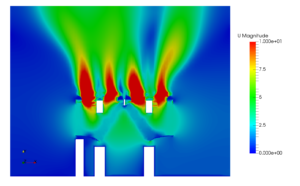

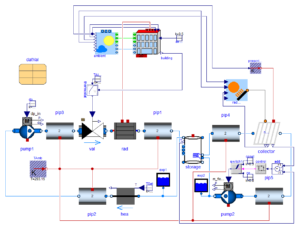

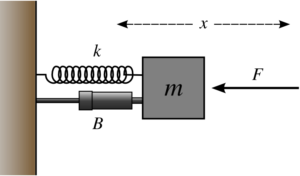

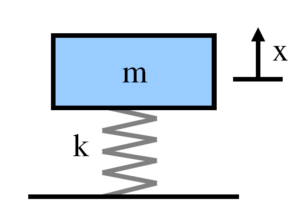

Flow frequencies in a duct flow if in-phase with structural eigen frequencies, can cause severe vibrations. Reduction or complete elimination of such flow induced vibrations might not even require major structural modifications! The basic question to be pondered about is how the frequencies are generated in a flow. The cause of a frequency in flow is due to fluctuation in pressure. Alternate high and low pressure zones can give rise to persistent flow frequency. So in order to eliminate flow induced structural vibration, the pressure variations in flow are to be eliminated. The combination of high and low pressure happens in several scenarios e.g., mixing of two flows, due to vortex formation or it may be due to a flow separation at bends. These kind of flows if taken care appropriately, undesirable pressure regions can be avoided. A sudden bend can be replaced by a smooth bend, fillets in duct can be used near bends, guide plates can be provided for flow to follow some specific trajectories and mixing can be gradual rather sudden.

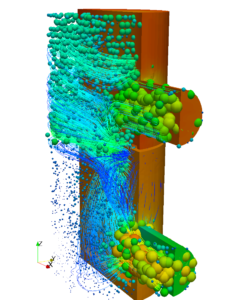

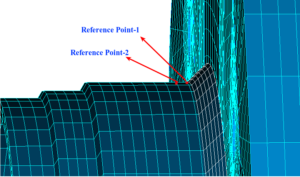

Analysis of duct flow with the help of CFD provides information on high pressure and low pressure regions during the flow, including flow separation and vortex formations. Both steady and unsteady behavior of flows could be analyzed. Accuracy of estimation depends on how well mesh is able to resolve boundary layer. k-epsilon and k-omega based turbulence models are mostly used for duct flow simulations.

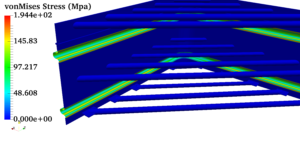

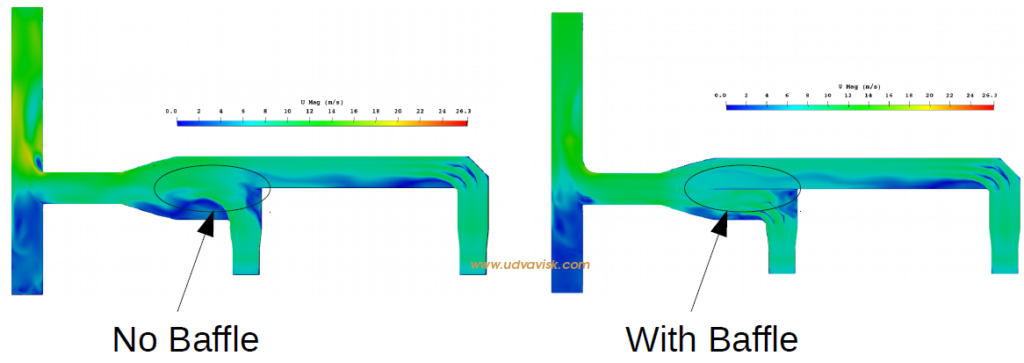

In this section, a duct flow simulation is discussed describing how baffles play a major role in reducing the flow non-uniformity. In reference to the velocity contours, the improvement in flow is apparent. Presence of baffles reduces the bend loss co-efficient, thus reducing the overall system resistance. So the corresponding drop in pressure values also can be observed in a pressure contour plot.

In tandem to flow induced vibrations, fan’s performance in a ducting system is also dependent least resistance paths. In duct flows fan is in place to overcome system resistance, hence should be carefully designed else the system might not satisfy the volume flow requirement in downstream. Increasing pressure resistance reduces the flow rate induced by fan, as per its performance curve. Baffles as flow guides could be used to reduce system resistance by avoiding flow separations.

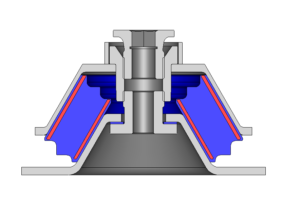

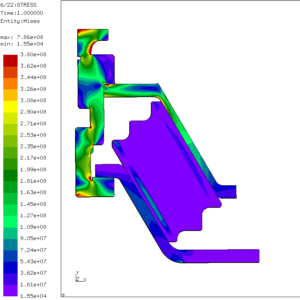

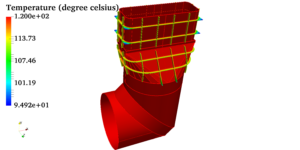

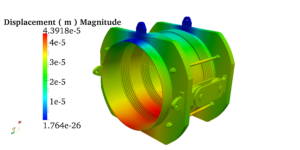

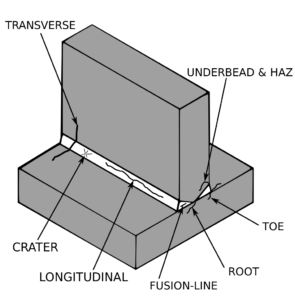

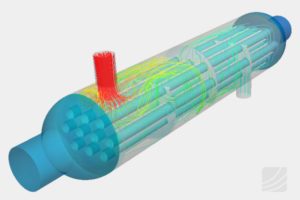

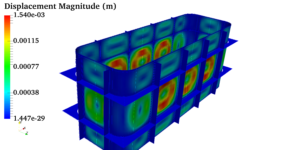

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.