CFD Analysis of Warehouse

CFD Analysis of Warehouse

A warehouse is a dedicated space used for the storage of goods and materials. It serves as a central point in the supply chain, where products are received, stored, and eventually distributed to customers or other locations. Warehouses are designed to efficiently manage inventory, optimize storage space, and facilitate the movement of goods in and out of the facility. They often feature various storage systems such as racks, shelves, and bins, along with equipment like forklifts and conveyors to aid in handling operations. Overall, warehouses play a crucial role in ensuring the smooth flow of goods within the logistics network of businesses.

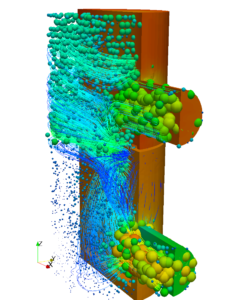

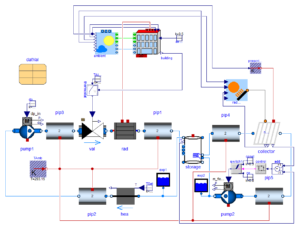

In a well-designed warehouse, achieving optimal airflow and thermal conditions is crucial for ensuring a comfortable and safe environment and preserving the quality of stored goods. Uniform airflow distribution is key to minimizing temperature variations and preventing stagnant pockets. The usage of jet-fans, fabric air ducts and High-Volume Low Speed (HVLS) fans play a vital role in enhancing air circulation and thermal distribution throughout the facility. These fans help to circulate air efficiently around storage areas to prevent stagnant pockets and break up thermal layers, ensuring consistent conditions across the warehouse. Combined with an appropriately sized and maintained HVAC system contribute to creating a conducive working environment and safeguarding product integrity and operational efficiency.

Computational Fluid Dynamics (CFD) offers significant advantages in optimizing warehouse design. By simulating airflow patterns and temperature distribution, CFD helps in determining the most efficient ventilation strategies. This includes identifying optimal locations for intake and exhaust vents to ensure uniform air distribution and minimize stagnant zones. By incorporating CFD early in the design process, warehouse layouts can be optimized to enhance operational efficiency, worker comfort, and safety. Overall, CFD provides valuable insights that contribute to the creation of well-ventilated, thermally controlled, and energy-efficient warehouse environments.

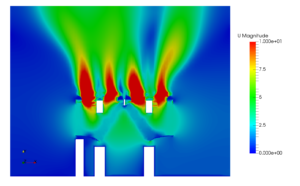

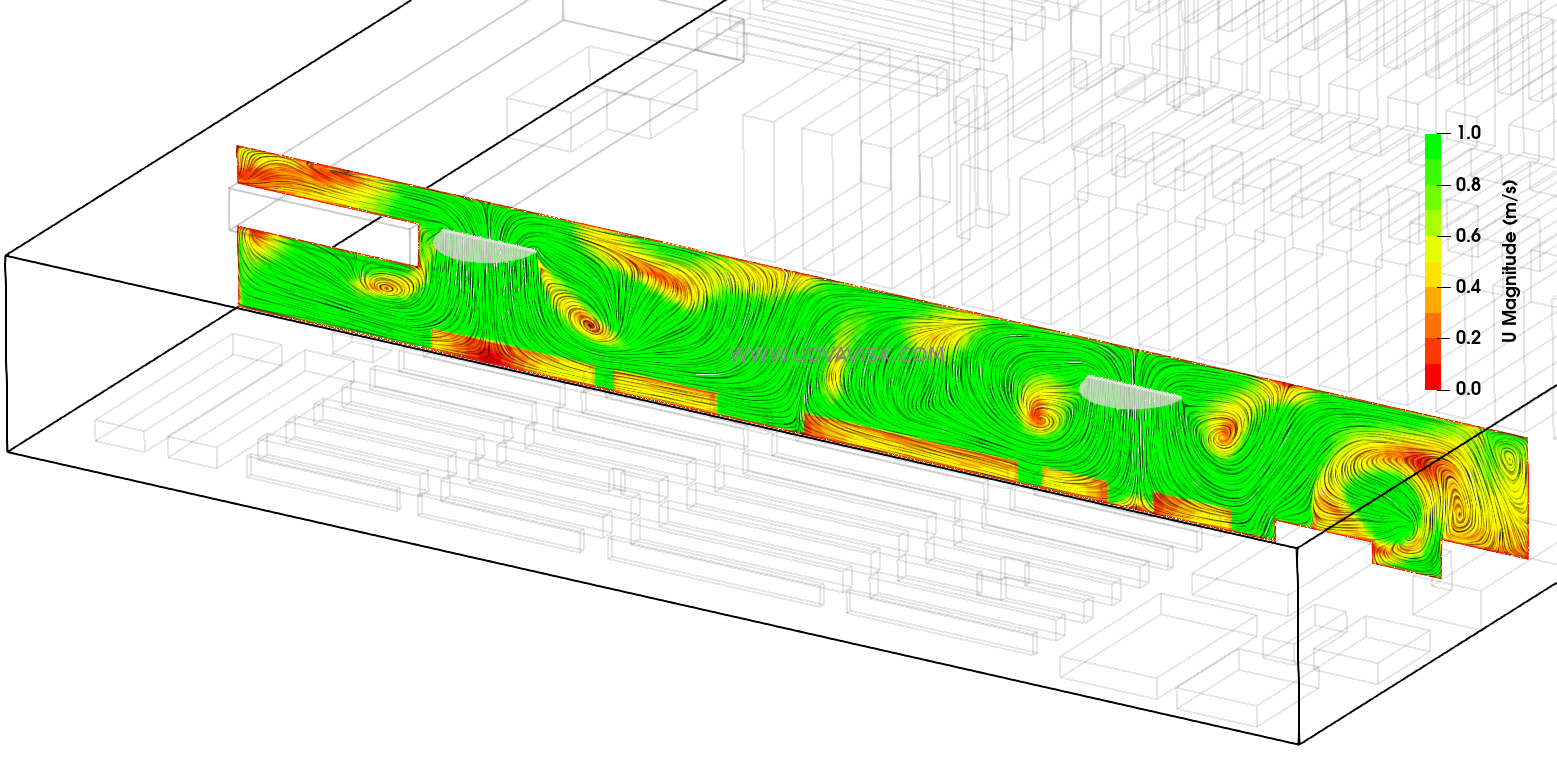

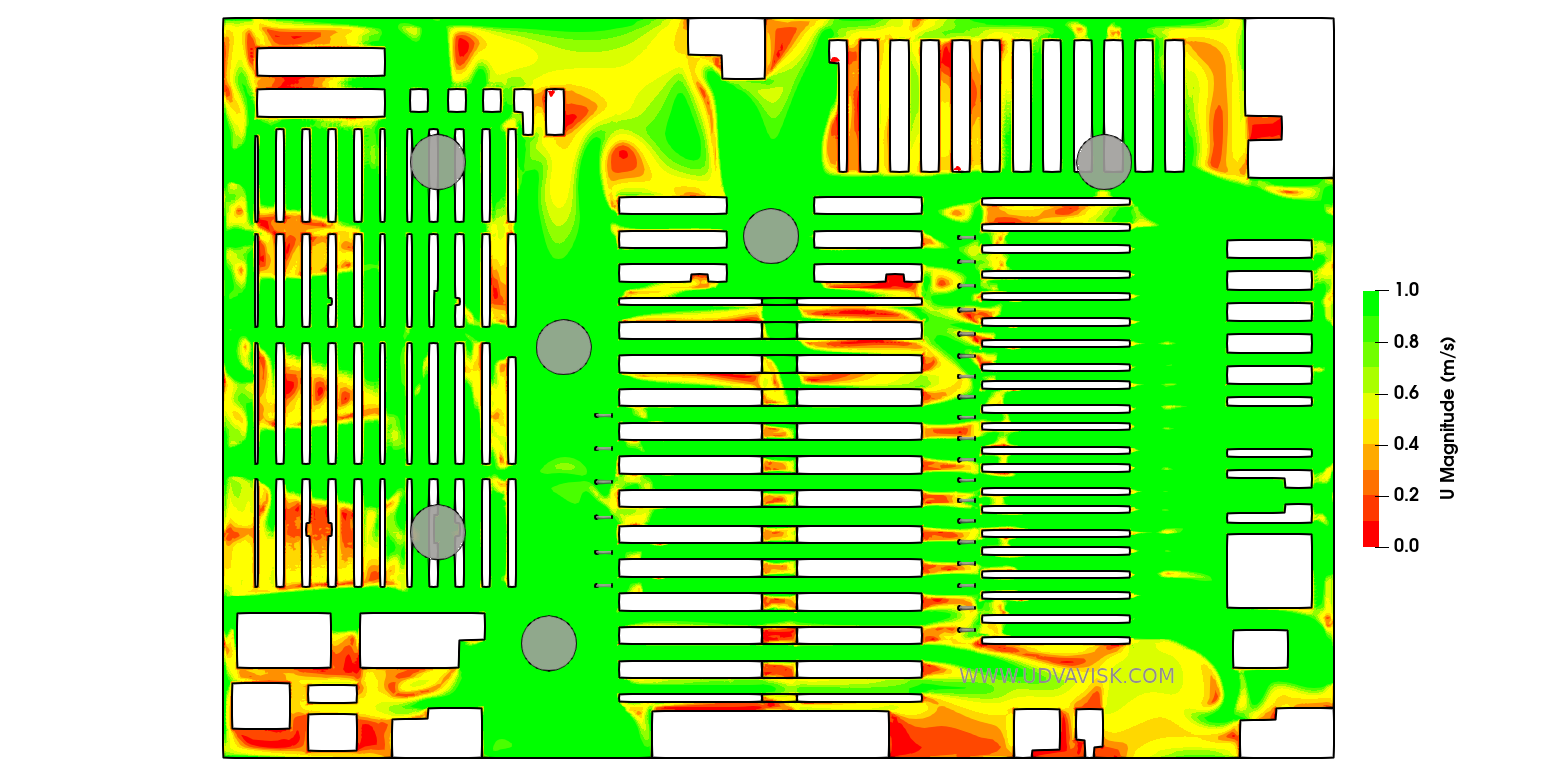

Below are some of the valuable insights that can be obtained using CFD when designing warehouses:

(i) Flow visualization within the warehouse (the below velocity streamline contour visualises the flow around the HVLS fans)

(ii) Identifying stagnant air-movement regions in human-dwelling areas (as shown in the below velocity contour with stagnation regions in red).

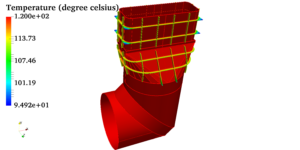

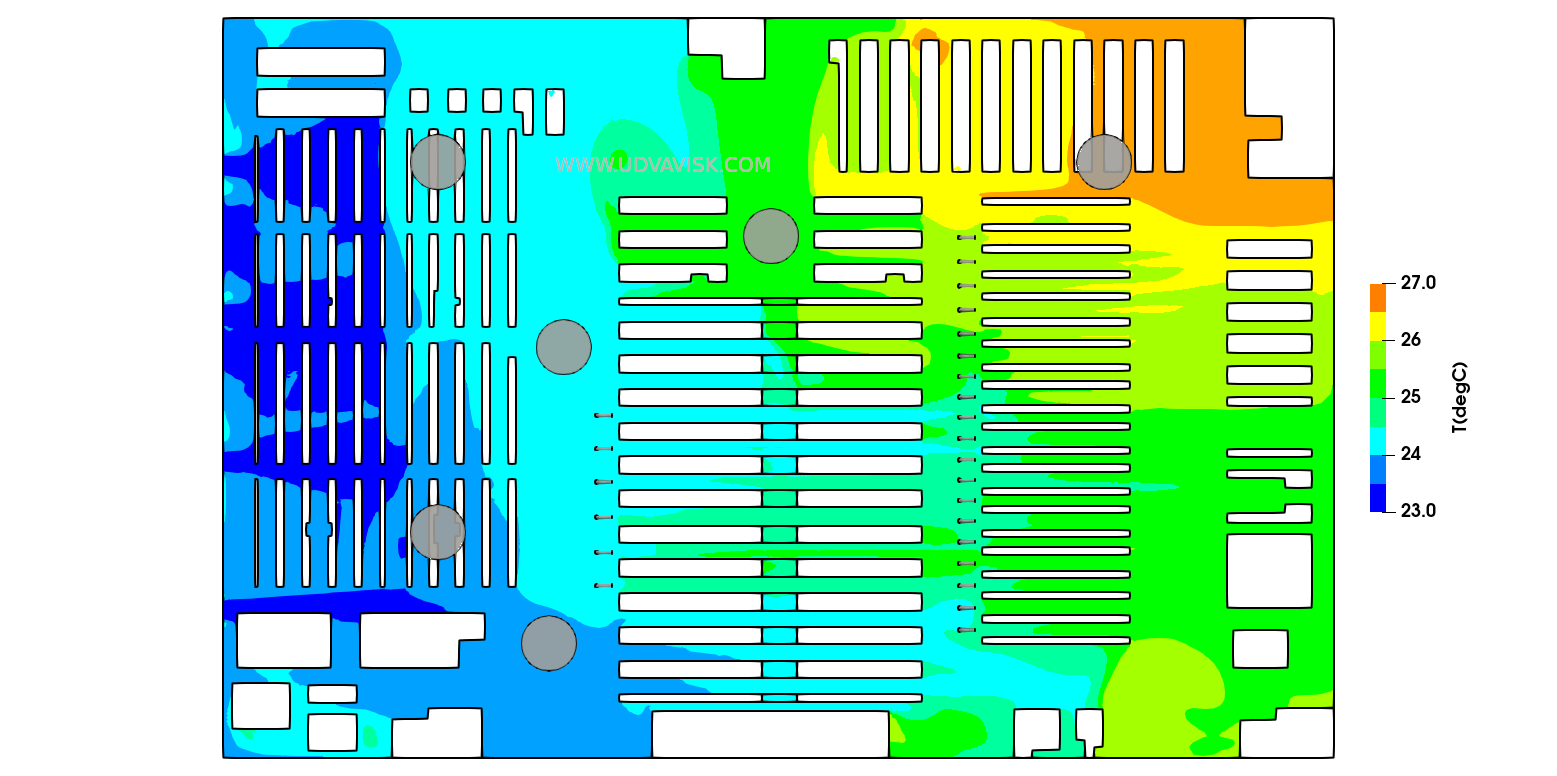

(iii) Modelling the temperature distribution within the warehouse (as visualized in below temperature contour)

In summary, warehouses are vital links in the supply chain, managing the storage and movement of goods with efficiency and precision. Achieving optimal airflow and thermal conditions is essential for ensuring worker comfort and product integrity within these dynamic environments. The integration of Computational Fluid Dynamics (CFD) brings a new dimension to warehouse design, offering insights into airflow patterns and thermal behaviour that optimize ventilation strategies. By harnessing CFD early in the design phase, warehouses can be tailored for peak operational efficiency, worker well-being, and safety. CFD’s ability to visualize airflow dynamics, identify stagnant areas, and model temperature distributions facilitates the creation of well-ventilated, controlled, and energy-efficient warehouse environments, essential for modern logistics networks.

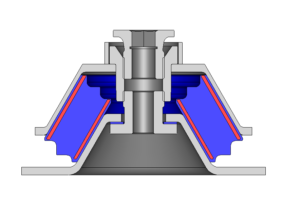

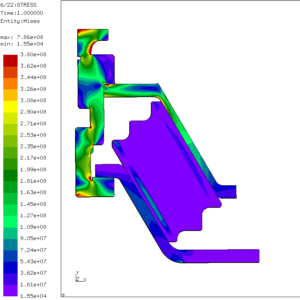

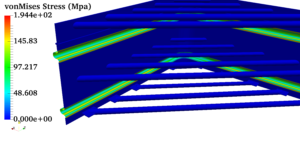

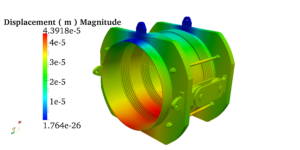

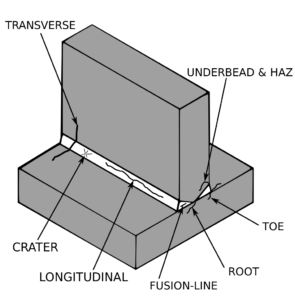

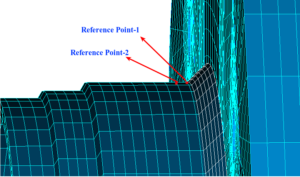

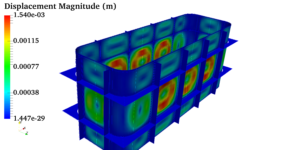

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.