Estimation of Overall Separation Efficiency, Grade Efficiency and Cut-off size for a Cyclone Separator

Estimation of Overall Separation Efficiency, Grade Efficiency and Cut-off size for a Cyclone Separator

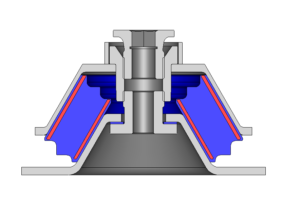

Cyclone separators are used for the purpose of separating dust particles from gas streams. It works on the principle of centrifugal force generated by vortex created due to tangential entry of fluid. The higher mass particles strike the wall of the cyclone and settles down in the dust-collector. Whereas the lighter particles go out of the vortex-finder arrangement at top. A CFD analysis has been carried out for a cyclone separator specific to a Cement Plant to estimate the flow-field inside the cyclone separator along with estimation of the collected and leaked particles.

The typical parameters for evaluating the performance of a cyclone separator are.

Pressure drop across the cyclone separator.

Overall separation efficiency

Grade efficiency curve

Cut-off size

CFD analyses can help in visualizing the flow-field inside the cyclone separator along with estimation of the collected and leaked particles. These estimations are used for determining performance parameters of the cyclone.

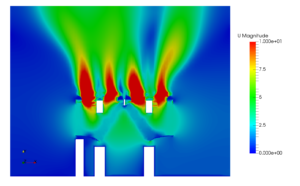

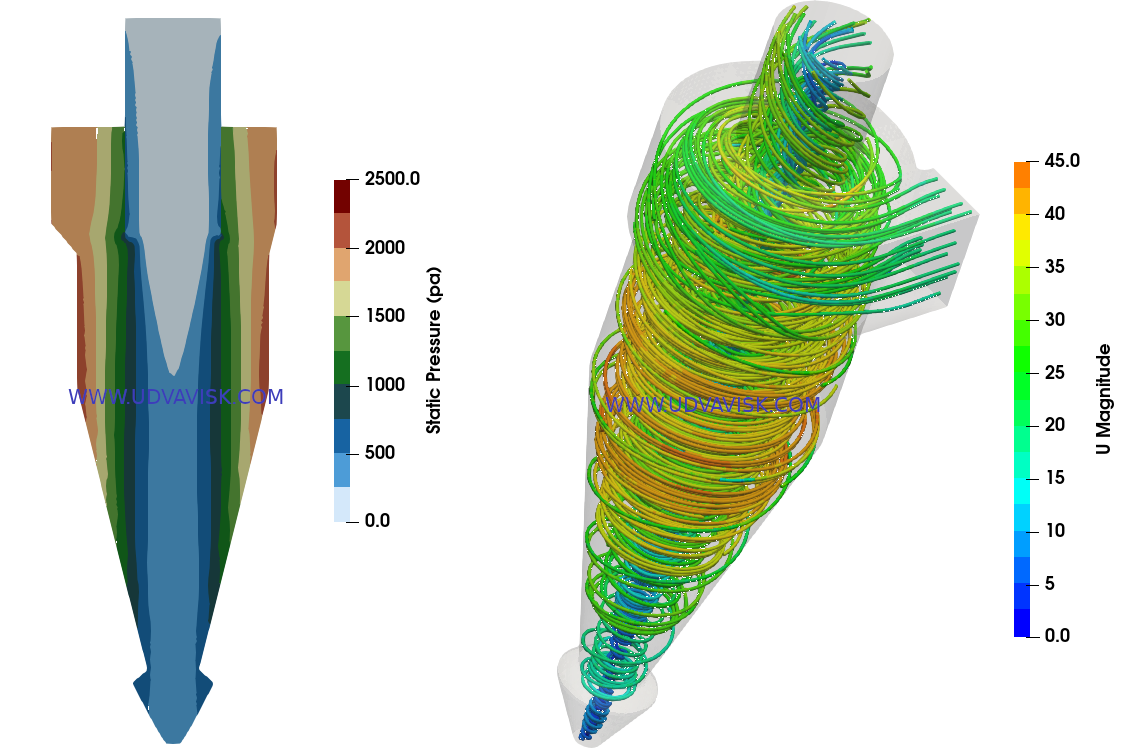

The pressure drop across the cyclone separator decides the performance metrics. A pressure contour as below can used to estimate the pressure drop across the separator.

As the gas stream enters the cyclone separator tangentially, a spiral vortex inside the cyclone separator is generated. The formation of a double vortex inside the separator can be observed with a streamline plot as shown above. An outer vortex for a downward flow towards bottom collector along with a second vortex making an upward flow of the gas-stream are available.

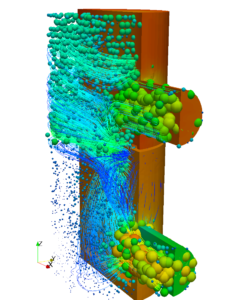

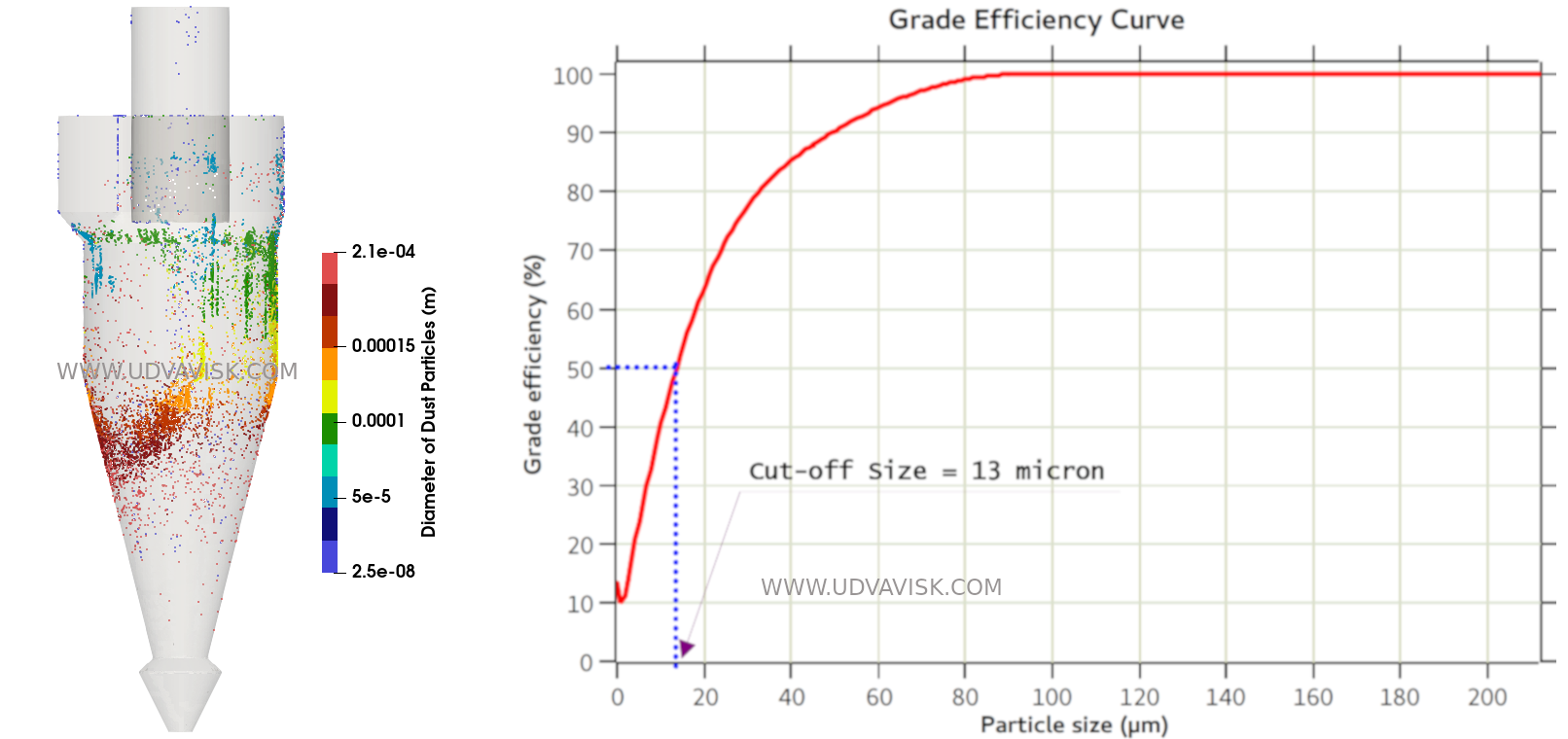

Dust particles are introduced at inlet of the cyclone separator. The particle distribution of different diameters can be observed in the below figure (represents distribution at 10 seconds after dust-particles were introduced).

A high overall collective efficiency (98.3%) has been observed owing to the high centrifugal force experienced by the dust particles. This centrifugal force directs the particles to strike to the cyclone separator wall and larger diameter particulate matter gets collected at the bottom as they have higher inertia. The grade efficiency of the cyclone for 11 different particle sizes that have been introduced is represented in the above graph. The cyclone separator at the simulated flow rate has a cut-off size of 13 µm.

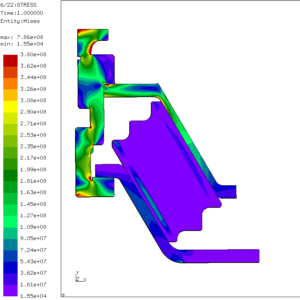

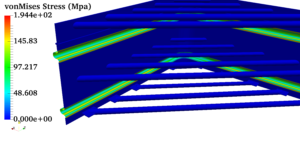

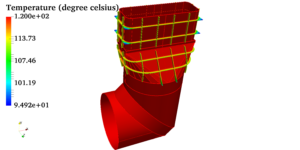

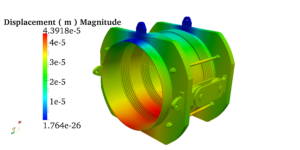

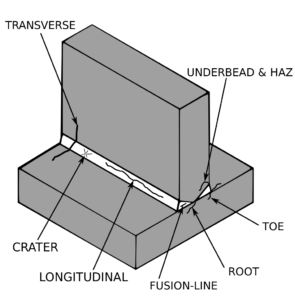

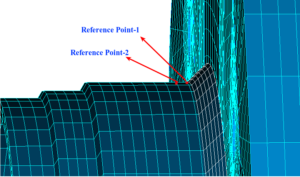

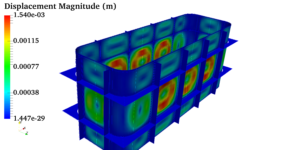

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.