Fire and smoke simulation in high-rise buildings

Fire and Smoke Simulation in High Rise Buildings

Fire in a high rise building is the worst nightmare of any occupant because of its destructive nature to cause property loss as well as human causalities. Fire along with its companion smoke causes lot of destruction to human habitat. Smoke contains toxic gases which upon inhalation can cause issues depending on the concentration of the smoke inhaled. Hence, many countries in the world have developed their own local guidance standards to design structures in such a way that fire can be contained. Fire and smoke simulation in high-rise buildings helps in fire emergency system design and performance evaluation.

Suppressing fire in a high rise building is a challenging task for local fire departments because it requires a high degree of liaison and methodical approach within the participating units. However, upon the instantiation of fire, it takes some time for the fire fighters to arrive at the location to extinguish the fire. Hence, the fire and smoke would continue to spread though spaces which exist between the fire resistant walls. To prevent the spread of smoke and to contain it a smoke extraction system can be used. The smoke extraction system typically uses the HVAC ducts which are already present within the building and a network of exhaust fans to remove the smoke within the fire zones. Fire & smoke simulation in high-rise buildings helps in evaluating the visibility during the fire mishap and evacuation plan

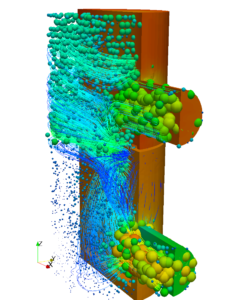

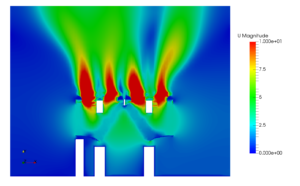

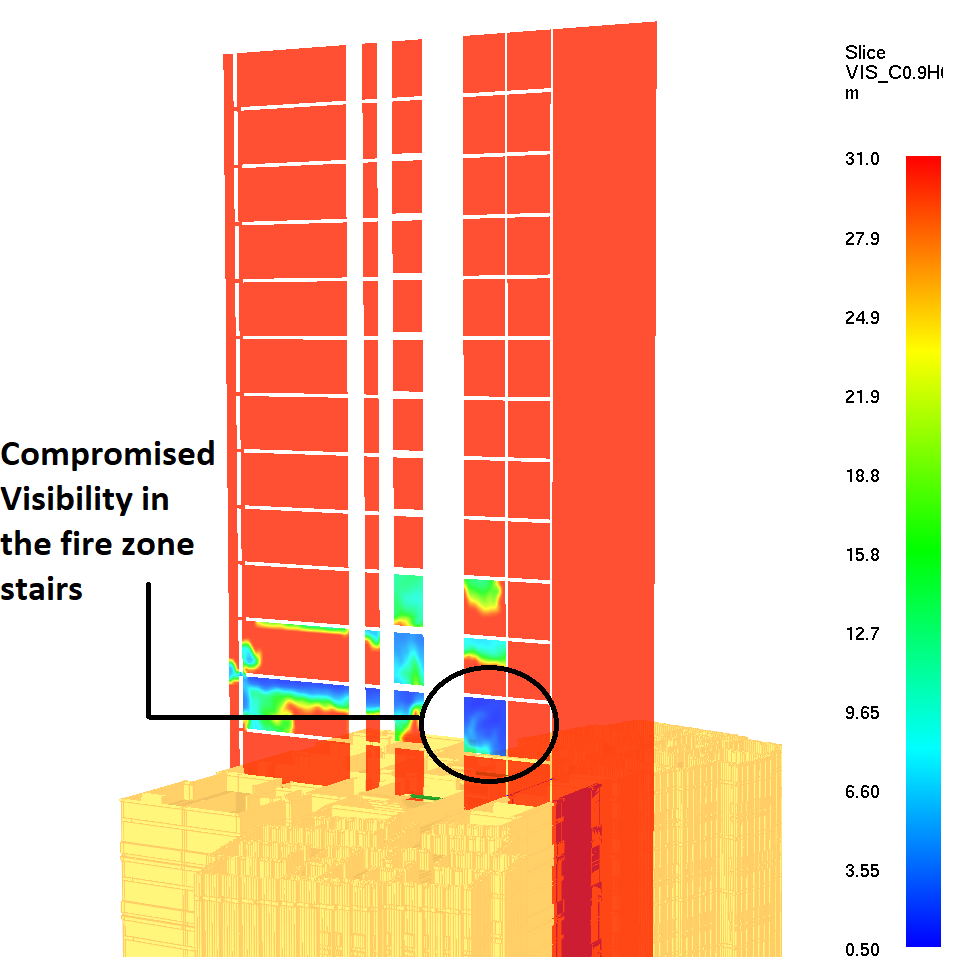

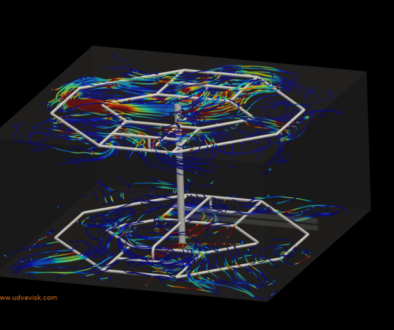

This study is performed to visualize the spread of smoke in a high rise building using CFD techniques. Several variables such as smoke concentration, the visibility due to presence of smoke, mass fraction of oxygen present in the fire zone is to be obtained to evaluate the severity of the smoke in the presence of a smoke extraction system.

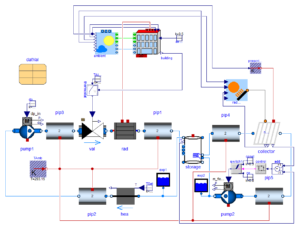

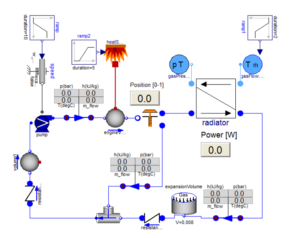

The high rise building consists of 26 floors and each floor typically has two smoke extraction vents, these smoke extraction vents deliver the smoke from the smoke zone to a central smoke shaft in the building via an exhaust vent in the shaft. Smoke detectors are present in each residence to detect the smoke and activate the exhaust vents. The exhaust rate of the vents is 0.8 m3/s. A HVAC network model is used to connect these vents without the use of ducts. A design fire of 600 kW is placed in the kitchen and a soot yield value of 0.2 kg/kg is chosen as a worst case scenario. The simulation is performed in such a way that the design fire is a steady state fire and it starts to burn instantly as the simulation starts. A hex dominated mesh is used to discretize the entire domain.

The visibility in the staircase which belongs to the zone where the fire exists is severely compromised and is found to be only 1m. Whereas, the maximum value of smoke concentration in the fire zone is determined as 0.00015 Kilogram per kilogram of air. Additional results such as oxygen mass fraction, water vapour mass fraction, smoke extinction coefficient, optical density, density of smoke, temperature are also determined.

Due to the presence of a smoke extraction system, it is observed that the smoke did not travel to the zones above the zone where the fire originated. A large volume of smoke is captured in the smoke shaft. This improved the conditions of visibility in the zones above the fire zone and the corresponding stair case. Since only a very little amount of smoke traveled to the other zones due to leakages in the building the level of concentration of smoke is also very little. The smoke delivered to the smoke shaft is disposed to the atmosphere via opening on top of the shaft.

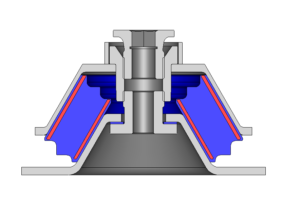

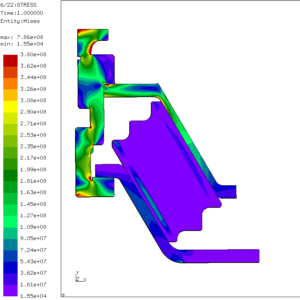

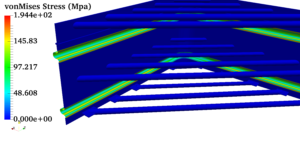

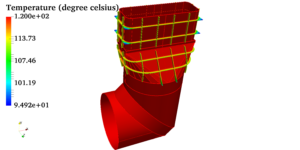

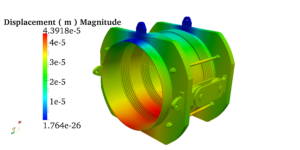

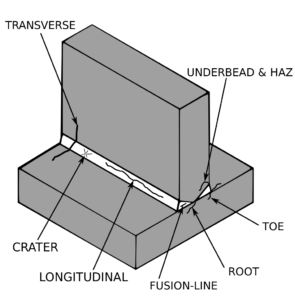

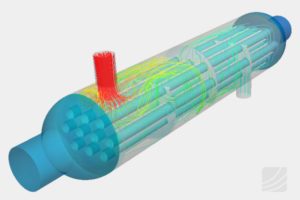

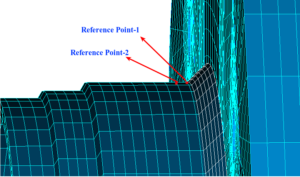

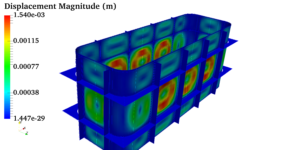

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.