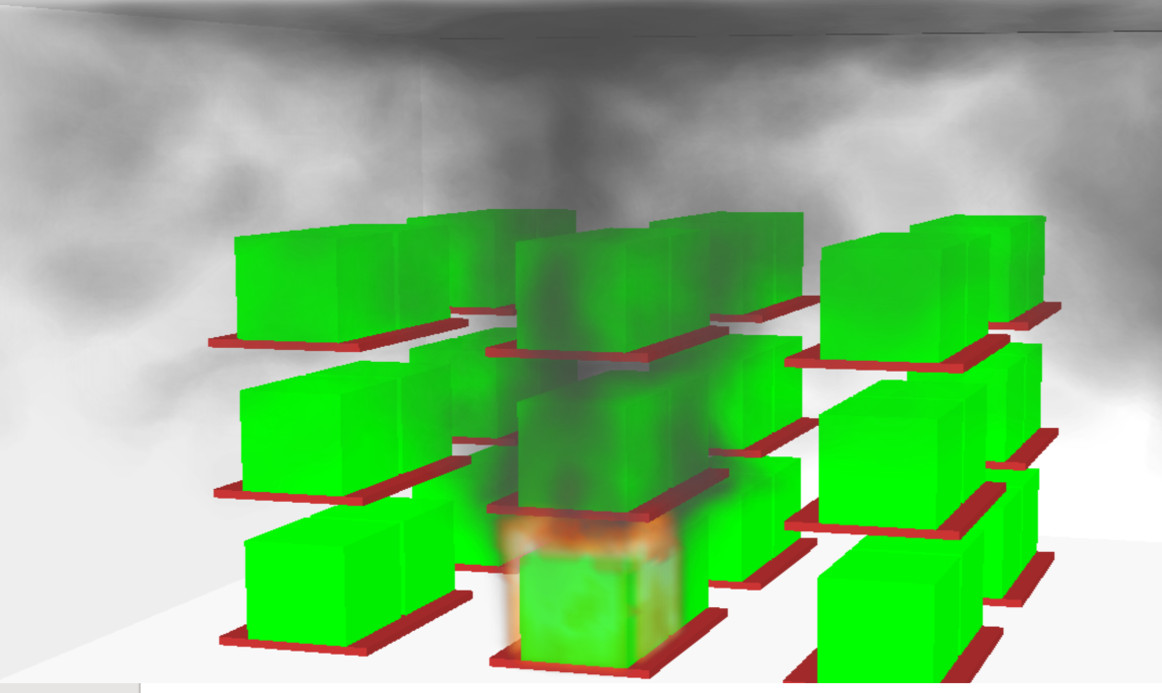

Fire and smoke simulation of a warehouse

Fire and Smoke Simulation of a Warehouse

The problem of fire growth prediction has historically been very challenging for engineers and scientists pursuing research in the field of fire dynamics. The lack of analytical solutions and computer capability has always hindered the march towards predicting the fire growth. However, even with the advent of numerical methods and supercomputers engineers are still facing with the biggest hurdle of determining the properties of materials and fire. The principal grail of this study is to determine the properties of fire as well as the nature of its growth in a warehouse containing stationary objects.

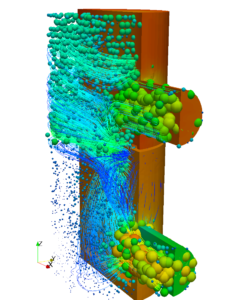

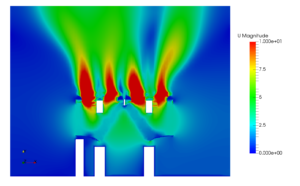

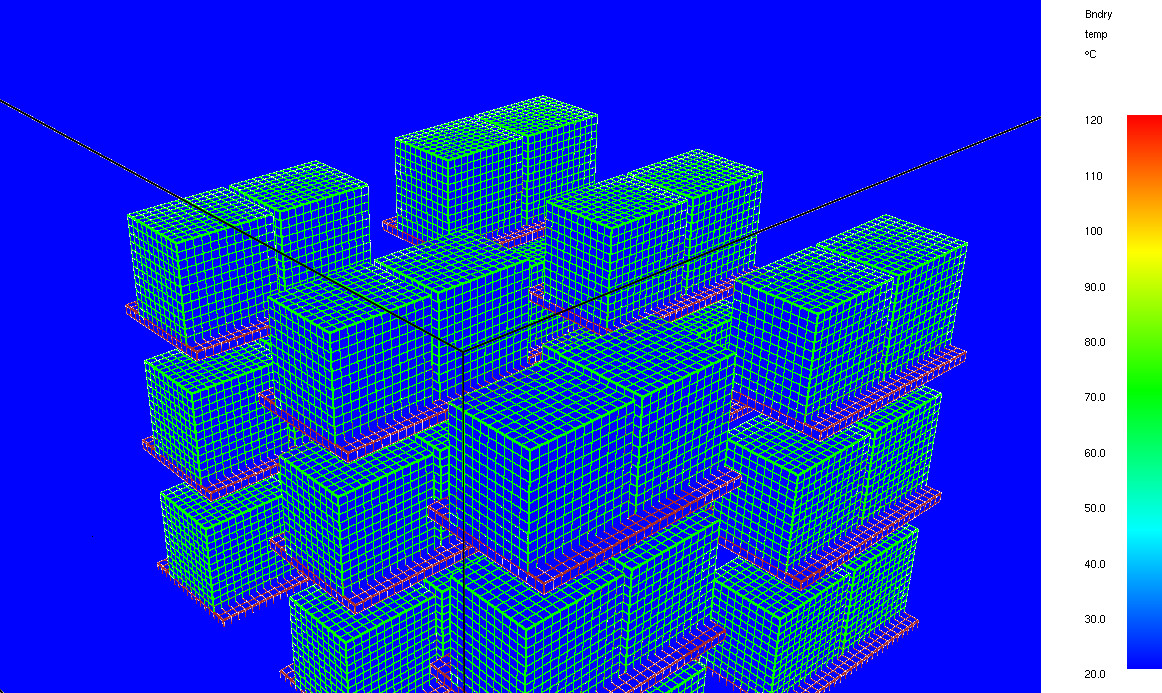

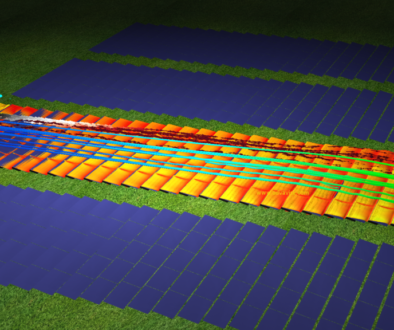

The geometry of the warehouse was constructed using an acclaimed fire dynamics solver called “FDS”. The dimensions of the zone subjected to fire was set based on recommendations from standard fire protection codes such as National Fire Protection Association(NFPA) 230 which a United States trade association. The fire suppression system such as sprinklers were also installed according to the code NFPA 13 which prescribes the standards for sprinklers in a zone which hosts solid fuel in a rack storage pattern. Row sprinklers are attached below every wooden pallet in the setup to prevent the fire growth. The transport of fire is usually treated as low Mach number buoyancy driven flows where the speed of sound is infinite. It is modeled mathematically using the large eddy simulation technique. This method numerically solves the Navier-Stokes equations by resolving a wide range of time and length scales all of which are directly affecting the flow domain. The entire domain is discretized into almost 87,500 cubic cells. LES modelling is usually a highly memory consuming technique, so the entire case is simulated in an adept computing machine.

For the sake of simplicity, it is assumed that sheets of A-4 paper placed in a cardboard container upon combustion produces cellulose. This is the only gas phase reaction occurring due to a high temperature ignition source. Cellulose, according to NFPA 704 poses considerable hazard upon combustion. Important parameters which govern the combustion are heat of reaction, emissivity, and the kinetic constants. The pre-exponential factors of solid Pyrolysis reaction of cardboard and paper were determined from several research documents. Thus cellulose being the only fuel, complex gas phase reactions are avoided to simplify the physics of the problem. It is further assumed that the wooden pallets supporting the main content also acts as fuel producing cellulose. A simple solid pyrolysis test of the cardboard box containing paper and wooden pallet is performed under controlled environment using the same CFD solver to obtain the values of heat release rate for the material. Experimental set ups such as cone calorimeters can also be simulated using FDS to obtain the peak values of heat release rates.

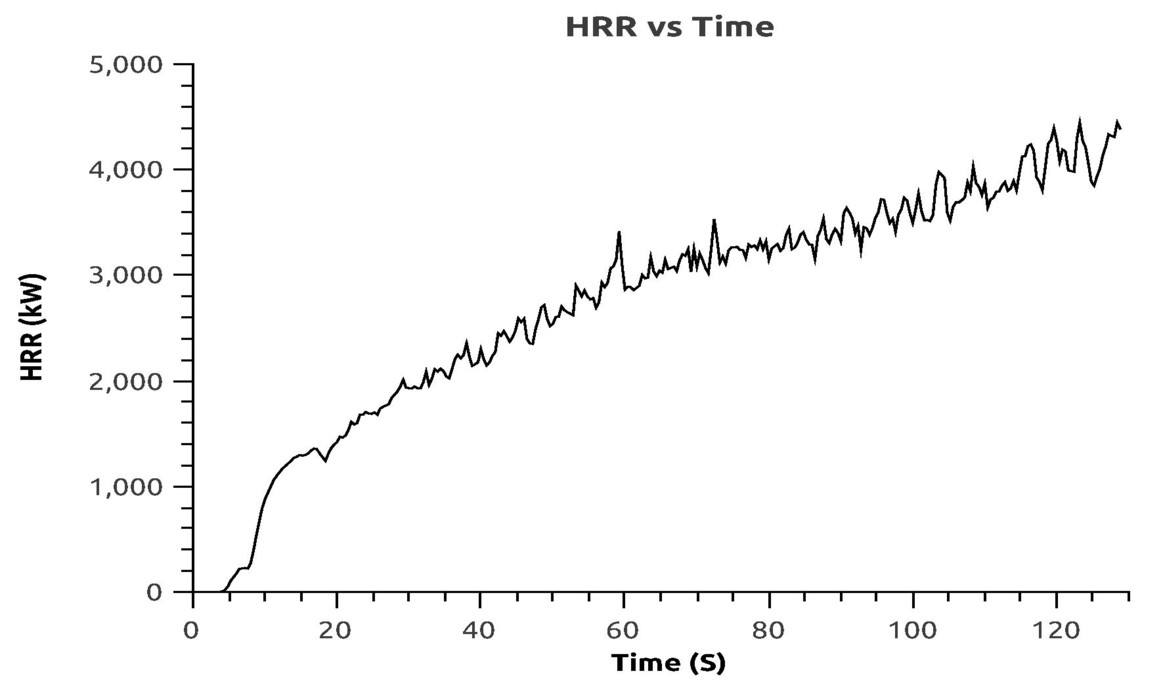

An ignition source producing 1000 degree fire is placed in the lower rack thus igniting the cardboard box in the Warehouse as its surface reaches the ignition temperature. The fire is allowed to progress using the HRR values obtained from the pyrolysis test. Figure 1.3 represents the peak values of HRR at discrete time intervals. The rate of computation depends on the amount of memory available. Mass transport occurs in between cells and the consumed mass is burnt away. It is to be noted that there is no charring residue in this combustion reaction. So, the entire solid fuel is converted to gas upon heat.

The physical model used is validated using standard experiments and the final HRR values for the entire warehouse fire were obtained as a function time. Additionally the transport of smoke was also visualized. Several variables such as elevated zone temperature, heat flux at the boundaries and the burning rate were also obtained by using sensor like devices available in the solver. The effectiveness of the fire suppression system was also studied. Since certain fires can lead to catastrophic and irrecoverable damage, it is quintessential that a precise prediction of fire is made. The greatest advantage of predicting fire would be the fact that is can facilitate the installation of a appropriate fire suppression system.

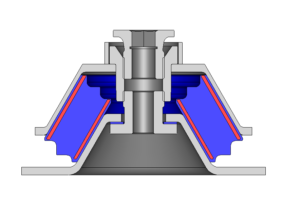

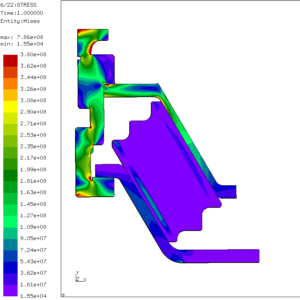

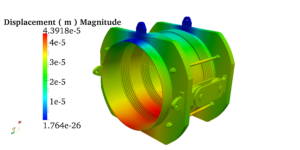

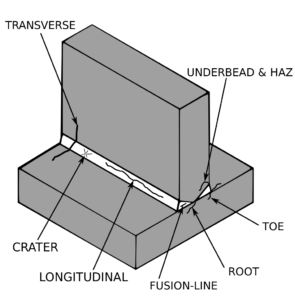

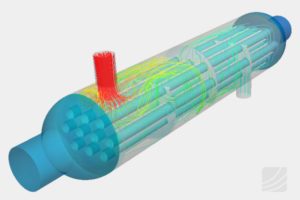

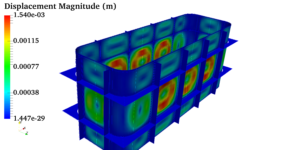

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.